- HOW TEMANE-MAPUTO ELECTRICITY TRANSMISSION LINE PROJECT IS GOING THROUGH TEST IN MOZAMBIQUE

- NAMIBIA INAUGURATED FIRST PLASTIC RECYCLING PLANTS

- PROGRESS MADE ON PIIM PROJECTS AS OVER 85% COMPLETED IN ANGOLA

- WORLD BANK KICK-OFF INSPECTION OF USMID PROGRAM IN UGANDA

- ALGERIA MINISTER RECIEVED HARBOR ENERGY CEO OVER ENERGY PARTNERSHIP

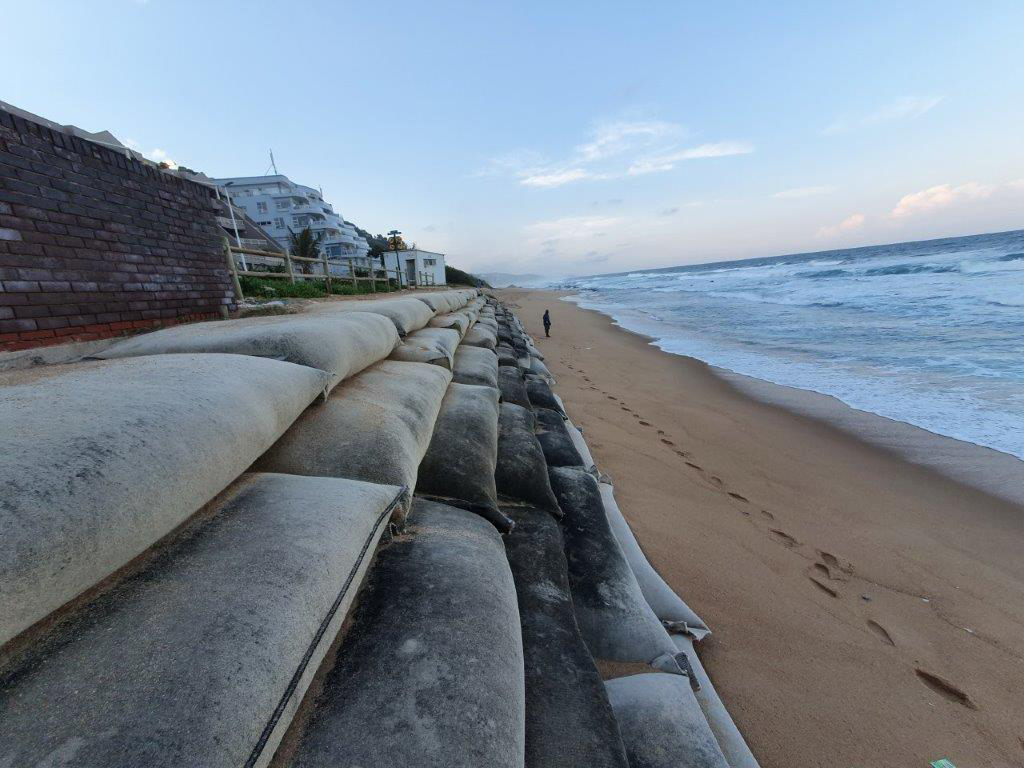

CARE FOR OUR COASTLINES

Fibertex manufactures geosynthetic sand containers (GSC’s) which are used in the construction of efficient protection structures for coastal protection, erosion control, dune revetments and slope stabilisation, as well as for emergency protection in floods.

“As coastal erosion becomes more prevalent, due to rising sea levels and changes in global weather patterns, it has become increasingly important to have well-engineered, durable and easily manageable coastal protection structures in place,” says Burger Fourie, Technical Sales Engineer at Fibertex SA. “Although using large sandbags as structural components of revetments is not new in environmental protection, Fibertex has made a substantial investment to design and manufacture a robust but soft GSC system, as an alternative to conventional rigid revetment structures. These robust GSC’s are a lightweight and workable geosynthetic substitute for traditional revetment systems utilising rock and even seawalls using concrete and reinforcing steel.

“The function of a GSC is to allow the free passage of water through the porous structure of the fabric and into the sand it carries, to absorb wave energy, while retaining the sand fill in the bag. This is unlike hard concrete structures, which predominantly protect by means of wave energy reflection, which could most likely have a negative long-term impact on adjacent structures.

“Fibertex FiberRock GSC’s were used for coastal rehabilitation at Umdloti beach in KwaZulu-Natal, over five years ago. The robust structure is still sound and highly effective in protecting the coastline.”

GSC’s consist of a strong porous base fabric, which is mechanically needle-punched together with a coarse anti-abrasion and vandal resistant (AVL) cover layer. This robust fabric combination offers a flexible structure that is able to retain a course fill medium – like sand – while allowing the free passage of water.

Fibertex AVL geotextile sand containers, which are manufactured from highly UV stabilised virgin Polypropylene (PP) fibres, can withstand the effects of repeated wave attacks in harsh coastal environments and are the perfect soft solution to beach rehabilitation and coastal protection.

Geotextiles used in the manufacture of GSC’s are required to withstand the effects of different environmental conditions from the geotextiles used for conventional separation, filtration, drainage and protection.

The Fibertex team has given particular attention to critical factors in the development of this system, including abrasion, perforation, puncture and UV resistance, tensile strength and elongation, as well as permeability and drainage.

GSC material selection is critical to the long-term stability of the entire structure. In the case of coastal protection applications, where high energy bi-directional flow conditions are encountered, needle-punched staple fibre (SF) geotextiles are preferred. They have proven to be durable and the staple fibre geotextiles do not delaminate under the harsh flow conditions expected from wave action.

Fibertex has selected virgin Polypropylene fibre, with excellent frictional and low density characteristics, as the basis for manufacturing its GSC fabrics. Polypropylene has better performance to weight ratio than other more dense polymers, such as Polyester. Although Polyester is a strong, durable polymer, Polypropylene is preferred globally in the manufacture of heavy grade/voluminous GSC fabrics.

Other important properties for appropriate product selection include the design of the revetment structure, where environmental influences such as wave velocity, wave amplitude, wave period and wave direction need to be taken into account.

Size selection of GSC’s for each application is also critical. Smaller GSC’s might be sufficient for less harsh conditions, but direct wave attacks often require a larger, more stable GSC’s. The correct installation procedure and optimal filling and closure of GSC’s prevent free movement of the bag, to ensure the long-term stability of the structure.

Fibertex GSC’s, which are available in sizes between 200 kg and 4 000 kg, can be used in riverine, lagoon and coastal protection works, depending on specific environmental and engineering requirements of the designed structure.

Fibertex SA has produced GSC’s for local projects, as well as large scale revetment structures in Africa, the Indian Ocean Islands, as well as in Europe and Australasia.

High-performance Fibertex materials – which comply with stringent quality, environmental and health specifications – play an important role in specialist sectors, including acoustics, automotive, bedding, building, composites, concrete, filtration, flooring, furniture, geotextiles, medico and wipes.

Fibertex products are manufactured to consistent quality standards at all production facilities globally and are supported by a technical advisory and back-up service.

For further information

Burger Fourie, Technical Sales Engineer, Fibertex South Africa (Pty) Ltd

Direct: +27 21 701 3569

Mobile: +27 (0)82 089 7731

Email: BURF@fibertex.com

Web www.fibertex.com

Released by Lindy Morton, Festivitas 083 268 6666 e-mail festivitas@dbnmail.co.za March 2022